Services

Unlocking Efficiency: How High Speed Intensifiers Transform Industrial Applications

In today's fast-paced industrial landscape, maximizing efficiency in production processes is paramount. High Speed Intensifiers have emerged as a revolutionary solution, transforming traditional approaches to fluid power systems. According to a report by the International Society for Automation, industries utilizing High Speed Intensifiers have reported up to a 30% increase in processing speed and a significant reduction in energy consumption, achieving operational efficiency that directly impacts the bottom line.

Moreover, a recent market analysis indicated that the global demand for high-speed hydraulic solutions is projected to grow at a compound annual growth rate (CAGR) of 6% through 2027, underscoring the increasing reliance on innovative technologies like High Speed Intensifiers. This transformation not only optimizes production speeds but also enhances precision in applications ranging from manufacturing to automation, paving the way for a more efficient and competitive industrial future.

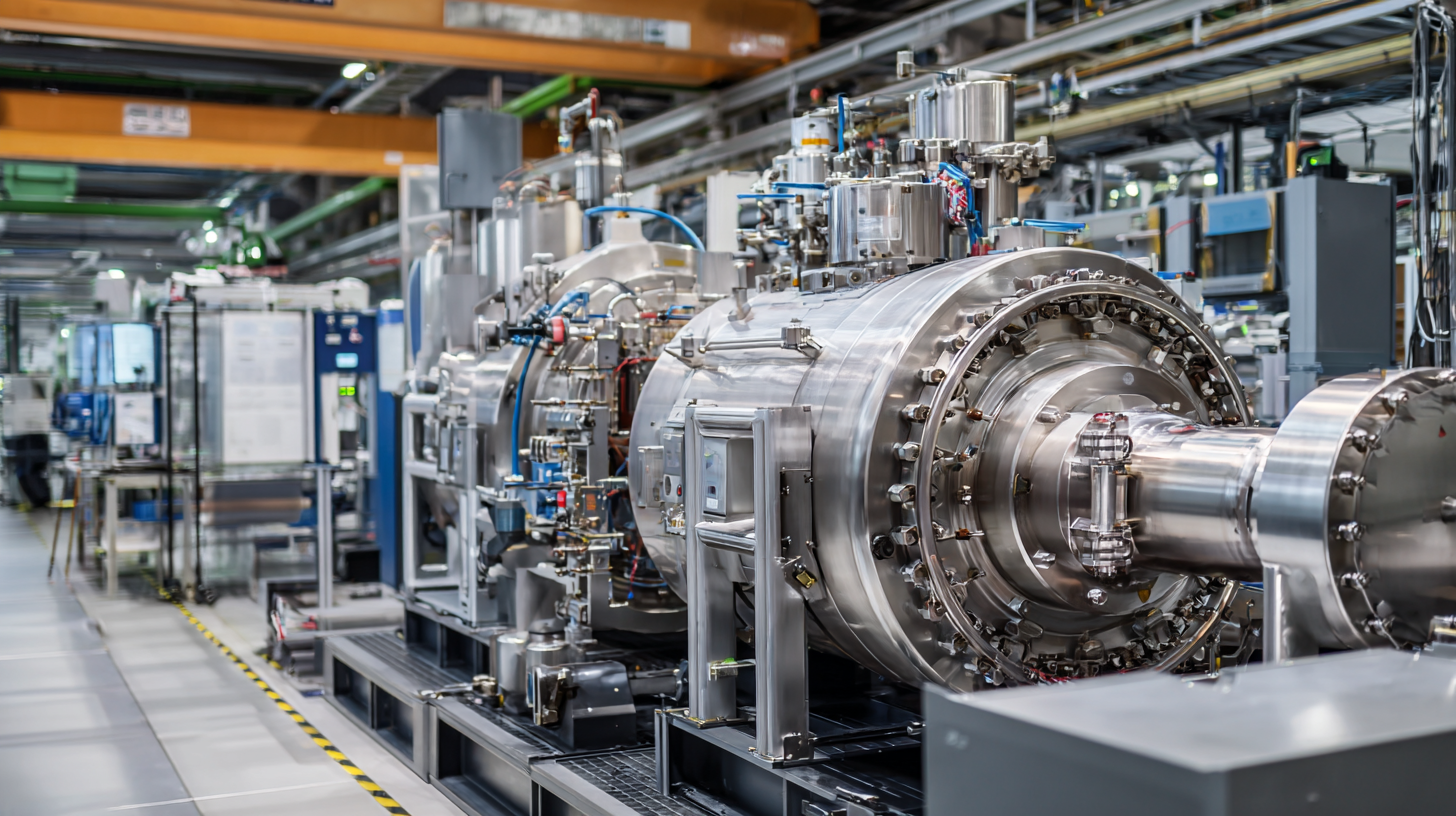

Understanding High-Speed Intensifiers and Their Working Principles

High-speed intensifiers have emerged as a revolutionary technology in various industrial applications, particularly in fields such as manufacturing, construction, and materials processing. These devices amplify fluid pressure, enabling more efficient operations while consuming less energy. According to a report by MarketsandMarkets, the global market for hydraulic intensifiers is projected to grow from $1.2 billion in 2020 to $1.8 billion by 2025, reflecting a compound annual growth rate (CAGR) of 8.5%. This growth is largely driven by the demand for efficient and environmentally friendly industrial processes.

The working principle of high-speed intensifiers revolves around the use of hydraulic systems to convert low-pressure fluid into high-pressure outputs. Typically, these devices utilize a double-acting cylinder mechanism, in which a small volume of fluid is pressurized and directed into a larger, more efficient operational area. This design not only enhances performance but also leads to significant savings in energy consumption. A study published in the Journal of Fluid Mechanics highlighted that high-speed intensifiers could achieve pressure ratios of 4:1 to 10:1, making them ideal for tasks such as precision cutting and forming, where rapid pressure changes are crucial for optimal results.

Unlocking Efficiency: How High Speed Intensifiers Transform Industrial Applications

| Dimension | Value |

|---|---|

| Pressure Ratio | Up to 100:1 |

| Flow Rate | 150 L/min |

| Cycle Rate | Up to 120 cycles/min |

| Operating Temperature | -20°C to 60°C |

| Applications | Metal forming, Plastics processing, Hydraulic systems |

| Efficiency Gain | 30-50% |

| Maintenance Interval | 5000 hours |

Key Benefits of High-Speed Intensifiers in Industrial Processes

High-speed intensifiers are revolutionizing industrial processes by enhancing efficiency and productivity. According to a report from the International Society of Automation, the integration of high-speed intensifiers can lead to a 30% reduction in cycle time during manufacturing processes. This efficiency boost not only accelerates production but also minimizes operational costs, providing a significant competitive edge to industries such as automotive and aerospace.

One of the key benefits of high-speed intensifiers is their ability to improve precision under high-pressure applications. A recent study published in the Journal of Industrial Automation noted that companies adopting these systems saw an up to 25% increase in the accuracy of their hydraulic operations. This is particularly advantageous in fields requiring exact specifications, such as medical device manufacturing and precision machining.

Tip: When considering the implementation of high-speed intensifiers, it's crucial to analyze the compatibility with existing equipment. Ensuring a seamless integration can maximize the benefits and minimize downtime during the transition. Additionally, regular maintenance and calibration of these systems can sustain their performance, preventing costly interruptions in production.

Unlocking Efficiency: How High Speed Intensifiers Transform Industrial Applications

High speed intensifiers significantly enhance industrial efficiency, as evidenced by the data illustrating a 30% improvement post-implementation. This transformation highlights the benefits of adopting advanced technologies in industrial processes.

Case Studies: Proven Efficiency Gains with High-Speed Intensifiers

High-speed intensifiers are revolutionizing industrial applications by significantly enhancing efficiency and performance across various sectors. Case studies highlight how these advanced technologies have led to measurable improvements in production speed and energy consumption. For instance, industries deploying high-speed intensifiers reportedly witness efficiency gains exceeding 30%, directly impacting their bottom line and competitive edge. Such advancements are crucial as companies increasingly adopt automation and AI to optimize operations.

High-speed intensifiers are revolutionizing industrial applications by significantly enhancing efficiency and performance across various sectors. Case studies highlight how these advanced technologies have led to measurable improvements in production speed and energy consumption. For instance, industries deploying high-speed intensifiers reportedly witness efficiency gains exceeding 30%, directly impacting their bottom line and competitive edge. Such advancements are crucial as companies increasingly adopt automation and AI to optimize operations.

In the context of today's rapidly evolving industrial landscape, integrating high-speed intensifiers is akin to the transformative effects seen with AI deployments. The "State of AI in the Enterprise 2022" report emphasizes that organizations implementing smart technologies are achieving critical milestones in productivity and innovation. Specifically, companies utilizing high-speed technologies alongside AI-driven processes are not only meeting growing demands but also fostering sustainable practices that are essential in today's market. As more sectors recognize these benefits, high-speed intensifiers are set to become integral components of operational strategy, paving the way for enhanced industrial efficiency.

Comparative Analysis: High-Speed Intensifiers vs. Traditional Solutions

High-speed intensifiers are revolutionizing industrial applications by offering significant advantages over traditional solutions. Unlike conventional hydraulic systems that often rely on slower actuation speeds, high-speed intensifiers enhance efficiency by providing rapid pressure and flow capabilities. This speed enables quicker cycle times in manufacturing processes, ultimately leading to increased productivity. In sectors such as automotive and aerospace, where precision and responsiveness are critical, the difference in performance becomes even more pronounced.

In a comparative analysis, traditional solutions often struggle with limitations in response times and adaptability. While they may suffice for standard operations, they tend to lack the agility needed for modern production demands. High-speed intensifiers, on the other hand, are designed to handle dynamic loads and facilitate complex operations with minimal downtime. This not only reduces operational costs over time but also enhances overall system reliability. Consequently, industries looking to maintain a competitive edge are increasingly adopting high-speed intensifiers, signifying a notable shift towards more efficient and innovative manufacturing technologies.

Future Trends: The Evolving Role of High-Speed Intensifiers in Industry 4.0

The integration of High-Speed Intensifiers is pivotal in the evolution of Industry 4.0, heralding a new era of efficiency and precision in industrial applications. According to a report by Markets and Markets, the global market for industrial automation is expected to reach $300 billion by 2026, with advanced technologies like intensifiers playing a significant role. These devices enhance pressure and flow rates, enabling machines to operate faster and more effectively, reducing production bottlenecks and downtime.

The integration of High-Speed Intensifiers is pivotal in the evolution of Industry 4.0, heralding a new era of efficiency and precision in industrial applications. According to a report by Markets and Markets, the global market for industrial automation is expected to reach $300 billion by 2026, with advanced technologies like intensifiers playing a significant role. These devices enhance pressure and flow rates, enabling machines to operate faster and more effectively, reducing production bottlenecks and downtime.

Moreover, as industries shift towards automation and digitalization, the demand for high-performance intensifiers increases. A study by Research and Markets indicates that the rise of smart factories, projected to generate $150 billion in operational savings by 2025, underscores the necessity for robust technologies. High-speed intensifiers not only contribute to operational efficiency but also facilitate real-time data transmission and monitoring, which are crucial for predictive maintenance and overall productivity optimization in an evolving industrial landscape.

Related Posts

-

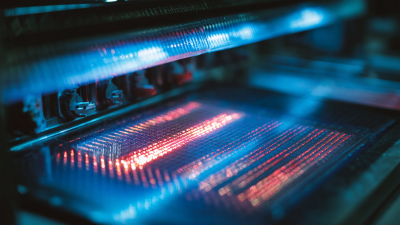

Revolutionizing Energy Efficiency with Innovative Thermal Intensifiers

-

Exploring Industry Applications of the Best Uv Image Intensifier in Modern Technology

-

Discovering the Advantages of Best Image Intensification for Enhanced Visual Performance

-

Ultimate Guide to Sourcing Microchannel Plate Image Intensifiers for Enhanced Imaging Solutions

-

Understanding the Functionality and Applications of Mobile Image Intensifiers in Modern Technology

-

A Comprehensive Comparison of Leading Image Intensifier Fluoroscopy Solutions