Services

Ultimate Guide to Sourcing Microchannel Plate Image Intensifiers for Enhanced Imaging Solutions

In the rapidly evolving field of imaging technology, the demand for high-performance solutions such as the Microchannel Plate Image Intensifier has surged significantly. According to a recent market report by ResearchAndMarkets, the global image intensifier market is expected to grow at a compound annual growth rate (CAGR) of 5.8% from 2022 to 2027, driven by advancements in security, military applications, and medical imaging. As professionals seek to enhance image quality in low-light conditions and improve detection capabilities, the application of microchannel plate technology has become increasingly vital. This ultimate guide aims to provide a comprehensive overview of sourcing Microchannel Plate Image Intensifiers, addressing key considerations, best practices, and the latest innovations to empower stakeholders in making informed decisions that elevate their imaging solutions.

Understanding Microchannel Plate Technology and Its Benefits for Imaging

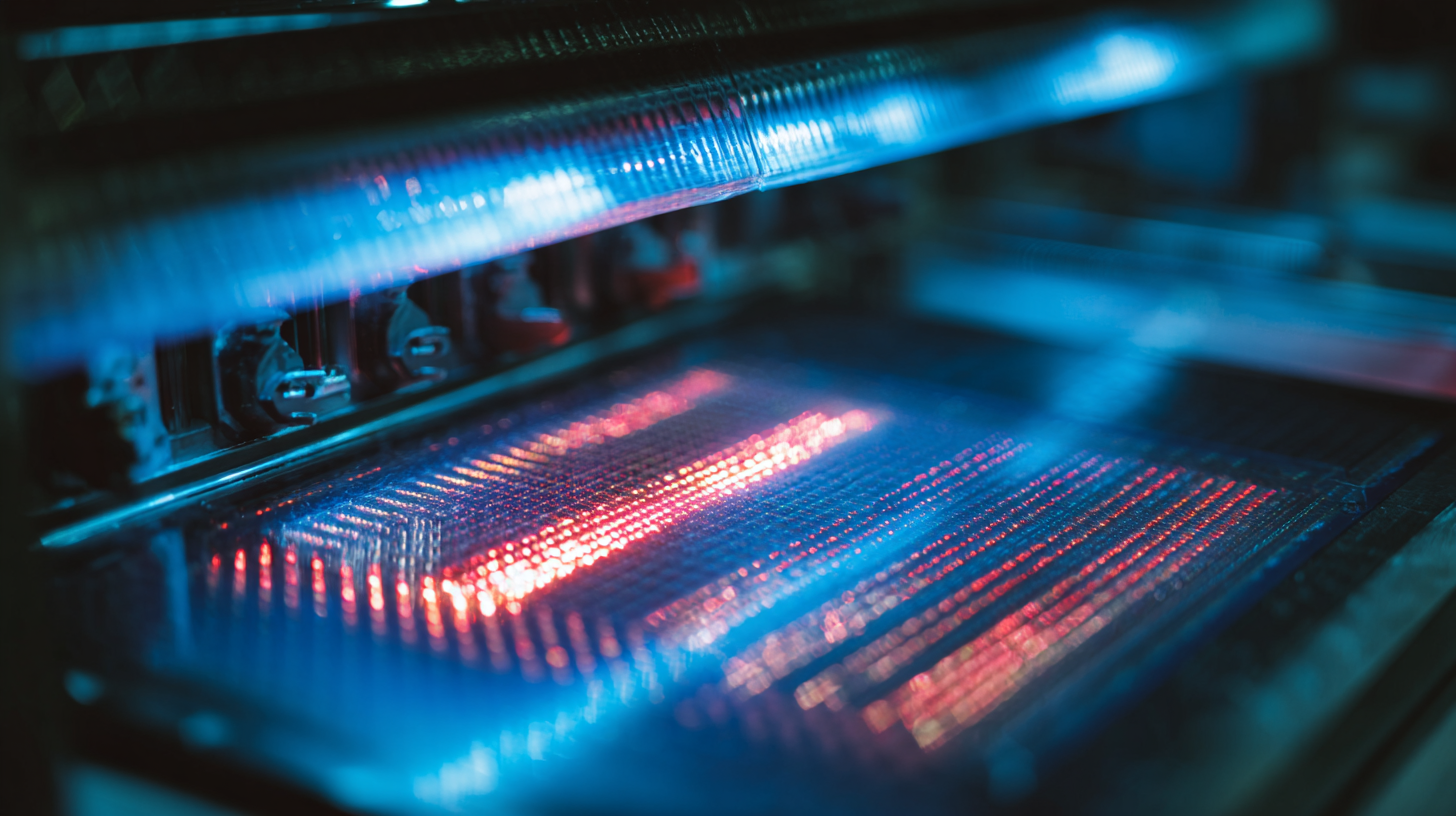

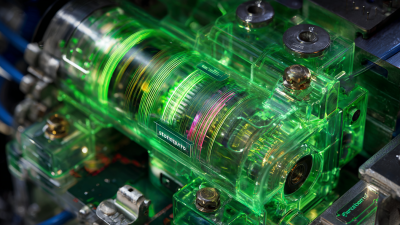

Microchannel plate (MCP) technology is revolutionizing imaging solutions, particularly in low-light conditions. By utilizing a series of microscopic channels, MCPs amplify incoming photons, leading to remarkable enhancements in image brightness and clarity. This technology offers several advantages, including increased resolution and improved signal-to-noise ratios. According to industry reports, systems employing MCPs can achieve a quantum efficiency as high as 40%, significantly outperforming traditional image intensifiers. This capability is particularly vital for applications requiring high fidelity in low-light environments, such as night vision and scientific imaging.

Recent advancements in MCP technology are also driving innovation in materials and production techniques. A collaboration between leading manufacturers has resulted in the development of lead-free MCPs through atomic layer deposition (ALD). This process not only enhances the precision of thin-film production but also improves the overall performance and longevity of the devices. Reports indicate that the adoption of ALD has led to a 20% increase in manufacturing yields and a corresponding reduction in production costs. As these technologies continue to evolve, the imaging industry is poised to benefit from unprecedented levels of efficiency and effectiveness in low-light image capture.

Key Specifications to Consider When Sourcing Microchannel Plate Image Intensifiers

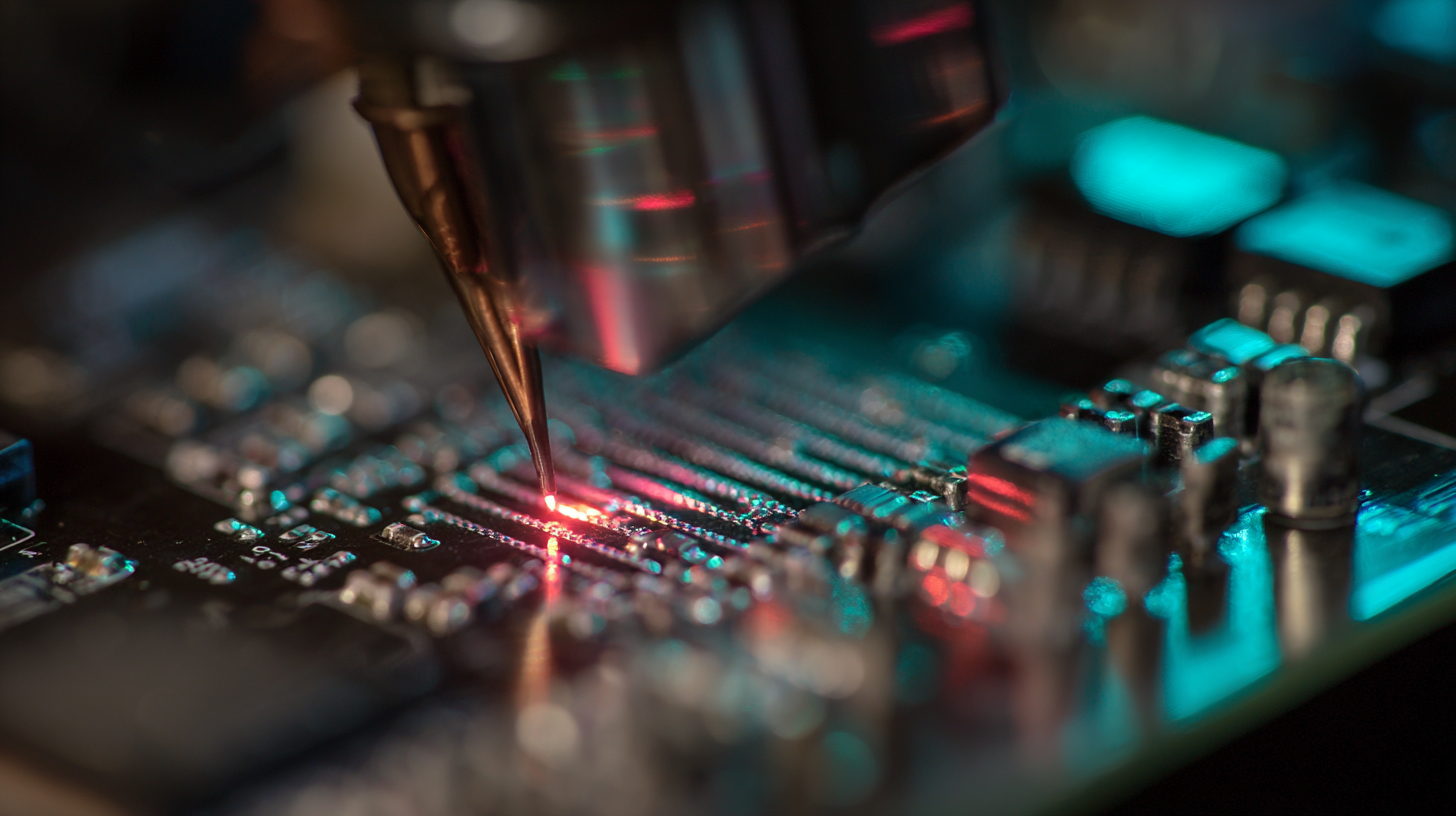

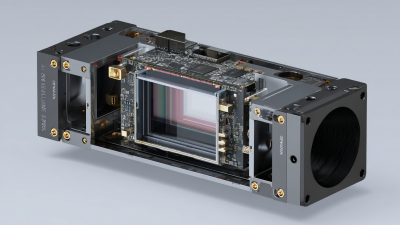

When sourcing microchannel plate image intensifiers, understanding key specifications is essential for ensuring optimal performance in various imaging solutions. These components are crucial for applications ranging from particle detection to mass spectrometry. One significant aspect to consider is the effective photon capture capabilities of the microchannel plates. Recent advancements in amorphous silicon-based designs have enhanced their efficiency, making them ideal for high-resolution imaging applications.

Tip: When evaluating microchannel plate image intensifiers, pay close attention to the gain factor and spatial resolution. High gain and precise resolution will significantly impact the quality of imaging. Additionally, it's important to assess the robustness of the material and the fabrication techniques used. For instance, new methods using combined laser beams for microchannel fabrication highlight a shift towards more precise and durable constructs, optimizing their functionality in various environments.

Moreover, consider the application's specific requirements, such as sensitivity to various wavelengths and the operating conditions of the imaging system. Understanding these parameters will enable you to select the most suitable microchannel plate image intensifier for your innovative imaging solution.

Comparative Analysis: Microchannel Plate vs. Traditional Image Intensifiers

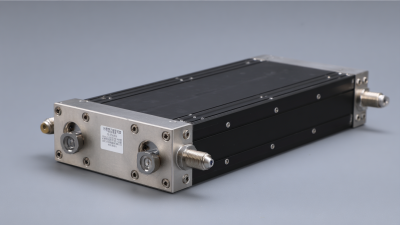

When assessing the latest trends in imaging technology, particularly in military applications, the debate between Microchannel Plate (MCP) image intensifiers and traditional image intensifiers becomes increasingly relevant. Recent advancements, such as those showcased in the new night vision equipment for the military, highlight the superiority of MCP-based systems. Unlike traditional approaches, MCP intensifiers boast greater sensitivity, allowing operators to discern details in low-light conditions more effectively. A recent industry report indicates that MCP image intensifiers can provide over 2000 lines of resolution compared to the 1000 lines offered by traditional options, significantly enhancing operational effectiveness.

Tip: When selecting an image intensifier, consider the specific operational environment. MCP systems are particularly ideal for missions requiring high-resolution imagery in minimal light, making them an excellent choice for military and surveillance applications.

In addition to sensitivity, MCP image intensifiers have superior spatial resolution and a more compact design, which translates to lighter, easier-to-deploy equipment. This is vital for ground forces who need agility without compromising on quality. According to market analysis, the demand for MCP technology is expected to grow by 15% over the next five years, driven by modern warfare's emphasis on enhanced situational awareness.

Tip: Always evaluate battery life and compatibility options with existing equipment when choosing an image intensifier, ensuring seamless integration with current systems for optimized performance.

Tips for Evaluating Suppliers and Ensuring Quality in Your Components

When sourcing microchannel plate (MCP) image intensifiers, evaluating suppliers is crucial for ensuring quality in your components. The performance and reliability of imaging solutions heavily depend on the quality of the MCP technology. Industry reports indicate that improper sourcing can lead to performance variations of up to 30%, significantly impacting outcomes in critical applications such as medical imaging, scientific research, and security surveillance. Thus, selecting a dependable supplier is paramount.

To effectively assess potential suppliers, it is essential to review their manufacturing processes and quality assurance protocols. According to a recent study by MarketsandMarkets, the global image intensifier market is projected to grow from $1.2 billion in 2021 to nearly $2 billion by 2026, highlighting the increasing demand for high-quality imaging solutions. Suppliers that adhere to international standards, such as ISO 9001, and who provide comprehensive documentation on component testing and validation are more likely to deliver reliable products. It's also advisable to seek suppliers with a proven track record in the industry, as recognized by certifications and customer testimonials. This diligence in supplier evaluation can significantly enhance the quality of MCP image intensifiers and, consequently, your imaging solutions.

Future Trends in Imaging Solutions: The Evolution of Microchannel Plate Technology

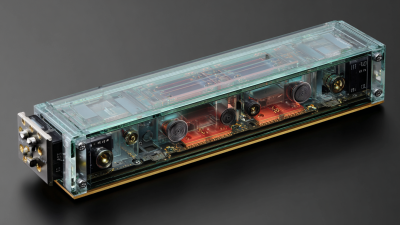

The realm of imaging solutions is undergoing a significant transformation, largely driven by advancements in microchannel plate (MCP) technology. Emerging trends are reshaping how we perceive and capture images, primarily in fields such as astronomy, medical imaging, and security systems. With the ability to amplify low levels of light while maintaining high resolution, MCPs are becoming pivotal in enabling clearer and more detailed images in low-light conditions. This evolution is not just about enhancing performance; it’s also about making these technologies more accessible and affordable for various applications.

Recent developments in materials science and engineering have led to the creation of more efficient MCP designs, allowing for greater sensitivity and faster response times. Innovations like integrated digital readout systems and multi-channel plates have further expanded MCP capabilities, facilitating real-time imaging that was previously unimaginable. As industries continue to invest in advanced imaging technologies, the integration of MCPs will likely play a crucial role in future solutions, paving the way for breakthroughs in both commercial and research environments. The trajectory towards smaller, lighter, and more powerful MCPs is set to redefine standards and expectations in imaging technology.

Future Trends in Imaging Solutions: Microchannel Plate Technology

Related Posts

-

Elevating Global Standards with the Best Microchannel Plate Image Intensifier Made in China

-

Ultimate Checklist for Sourcing the Best Microchannel Plate Image Intensifier Globally

-

Future Innovations in Best Fluoro Image Intensifiers Shaping 2025 Industry Trends

-

How to Select the Best Microchannel Plate Image Intensifier for Your Specific Needs

-

Understanding the Functionality and Applications of Mobile Image Intensifiers in Modern Technology

-

10 Essential Image Intensifier Technologies Transforming Global Procurement Trends